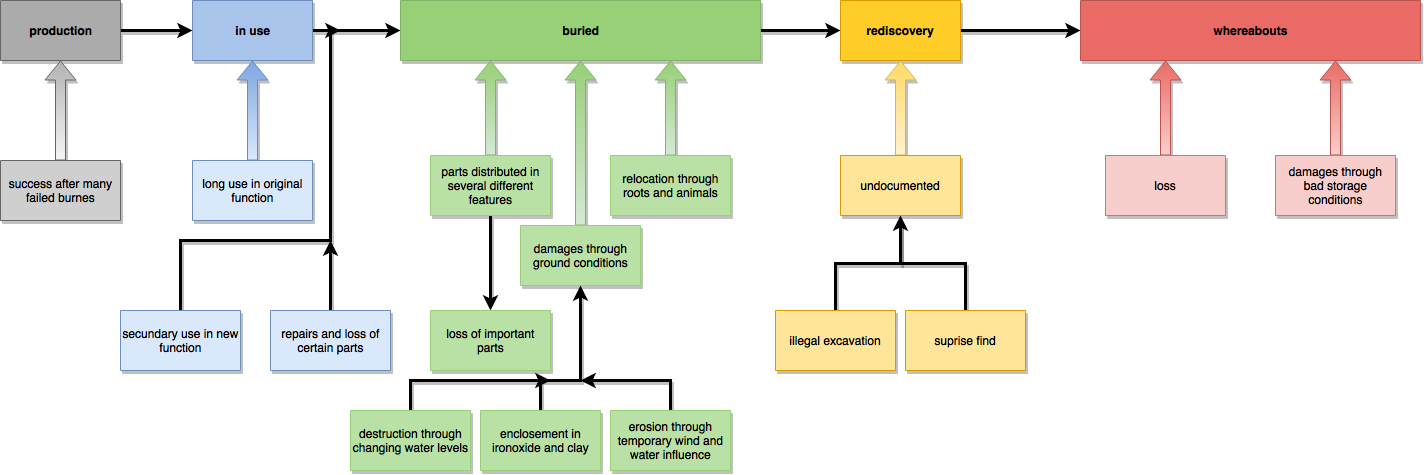

tl;dr: Reprinting fragmented objects can open various great possibilities for science, education, and museums. Especially the details of modern full-color printer could create very realistic looking replicas without endangering the fragile originals.

The following 3D printed archaeological find, was made possible through Formwerk3D.

Pottery finds from settlements

Ceramic objects from settlements are normally very fragmented. It’s unlikely to find all pieces because of the wide spread of pieces. This is because of the different kinds of preservation and transmission of objects.

Ideal case of preservation

After its successful creation, the pottery is in use at the moment of the settlement phase. The duration of the object lifespan is unknown and can only be roughly estimated. After a while in use, the pottery will eventually break and become unusable. So it will be discarded into some kind of ditch. This ditch will preserve all pieces until it is excavated by archaeologists. They will list, describe, reconstruct and in some case be displayed in a museum.

Worst case-Scenario

After many tries, the pottery finally gets successfully produced in the burning process. And its primary use begins. The failed objects were discarded or reused as base material for new pottery.

After a while, the objects maybe break and gets either repaired or get reused in a secondary function. In the end, the different fragments from the using phases all get thrown away and become eventually buried in one or several features. This discarding process can stretch over a long time, so the different fragments of one pottery object can be in different features over a wide area.

After the end of the starting settlement phase, other settlers build their own houses in the same area and younger features start interfering with older ones. Old traces get lost or mixed up with newer materials. Some parts of the region may also erode through wind or water. In all this time the shards are strongly influenced by the ground conditions and animals or roots.

Finally, the fragments become excavated. In the worst-case scenario, they are discovered randomly by non-professionals or illegal excavations. They don’t get properly documented or classified and if they are not thrown away they could get finally damaged by bad storage conditions.

Possibilities of modern 3D technologies

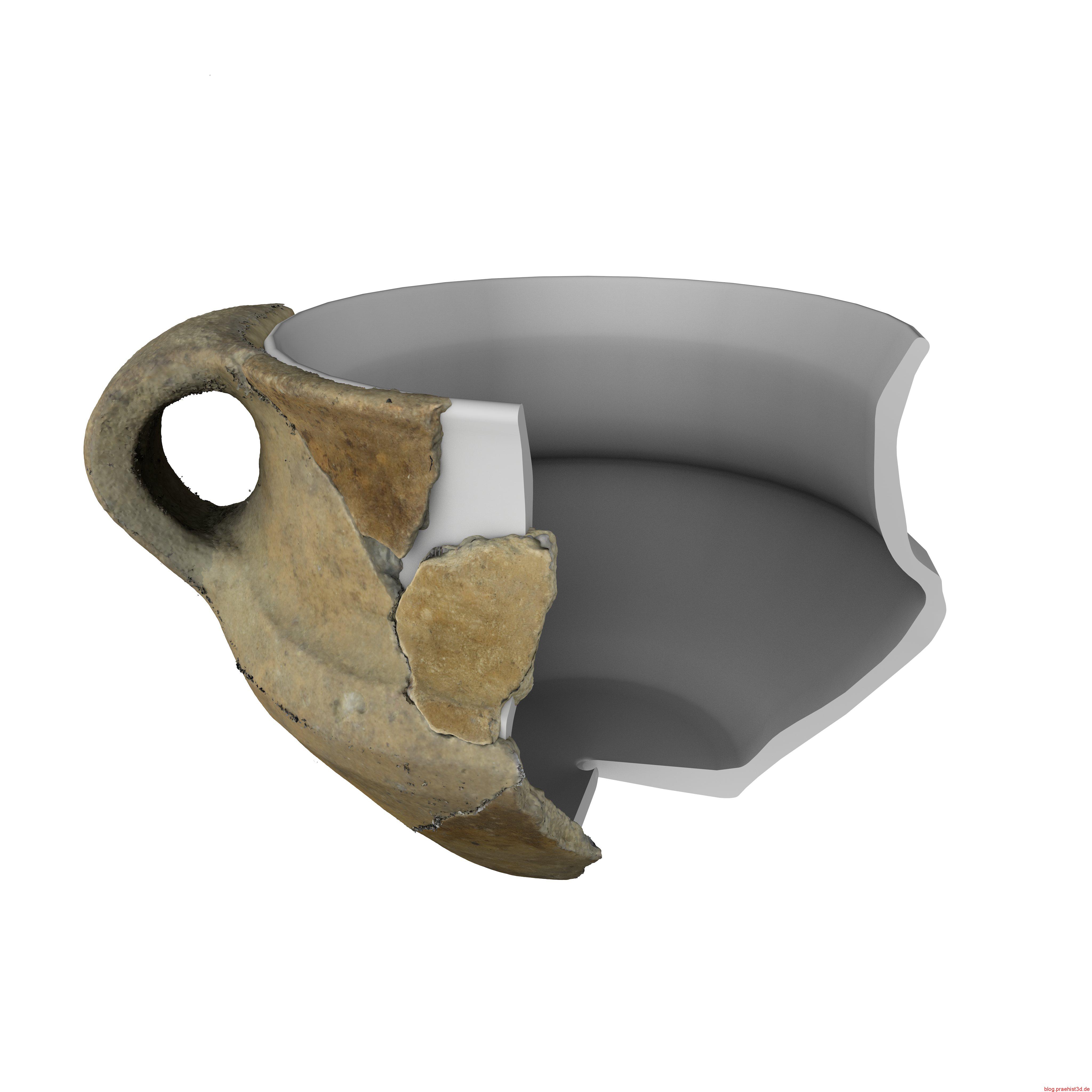

As mentioned in former posts, objects can easily become digitized. These digital data is easier to handle and is fast accessible. These models could get used to analyzing finds and can be displayed and transferred in seconds to a wide clientele. It’s also possible to reconstruct and reassemble finds this way without any harm or transformation to the originals.

3D print

Modern 3D print is an easy and affordable way to replicate virtual models. These can show the original conditions or be the result of different reconstruction and assembling stages. Different Materials can be used to accomplish different goals.

Printing in plastics

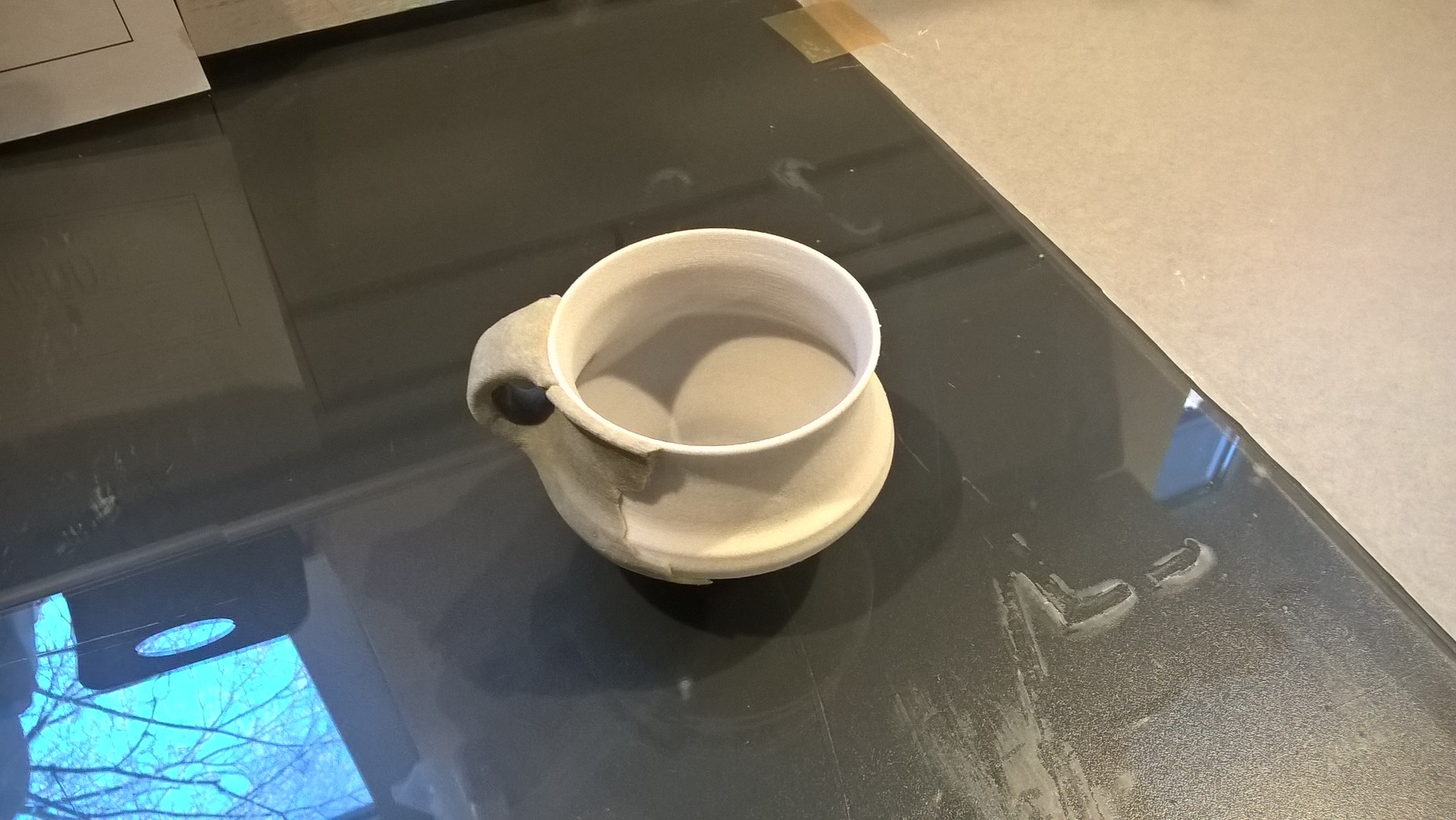

The most common are printers that use some kind of plastic. Typically, the resulting object is monochrome or a combination of two colors. This can be very useful to distinguish between “original” and reconstructed parts of the model. The advantages of these printers are first and foremost the low costs per print. Also, they are relatively compact, and the resulting objects are durable and can be really detailed, depending on the used printer.

On the other side are products from plastic printers, a very abstract copy of the real object. For example, a 3D plastic print can only reproduce the surface and form, not the color or feel of the original. Also, the weight is not nearly feeling real.

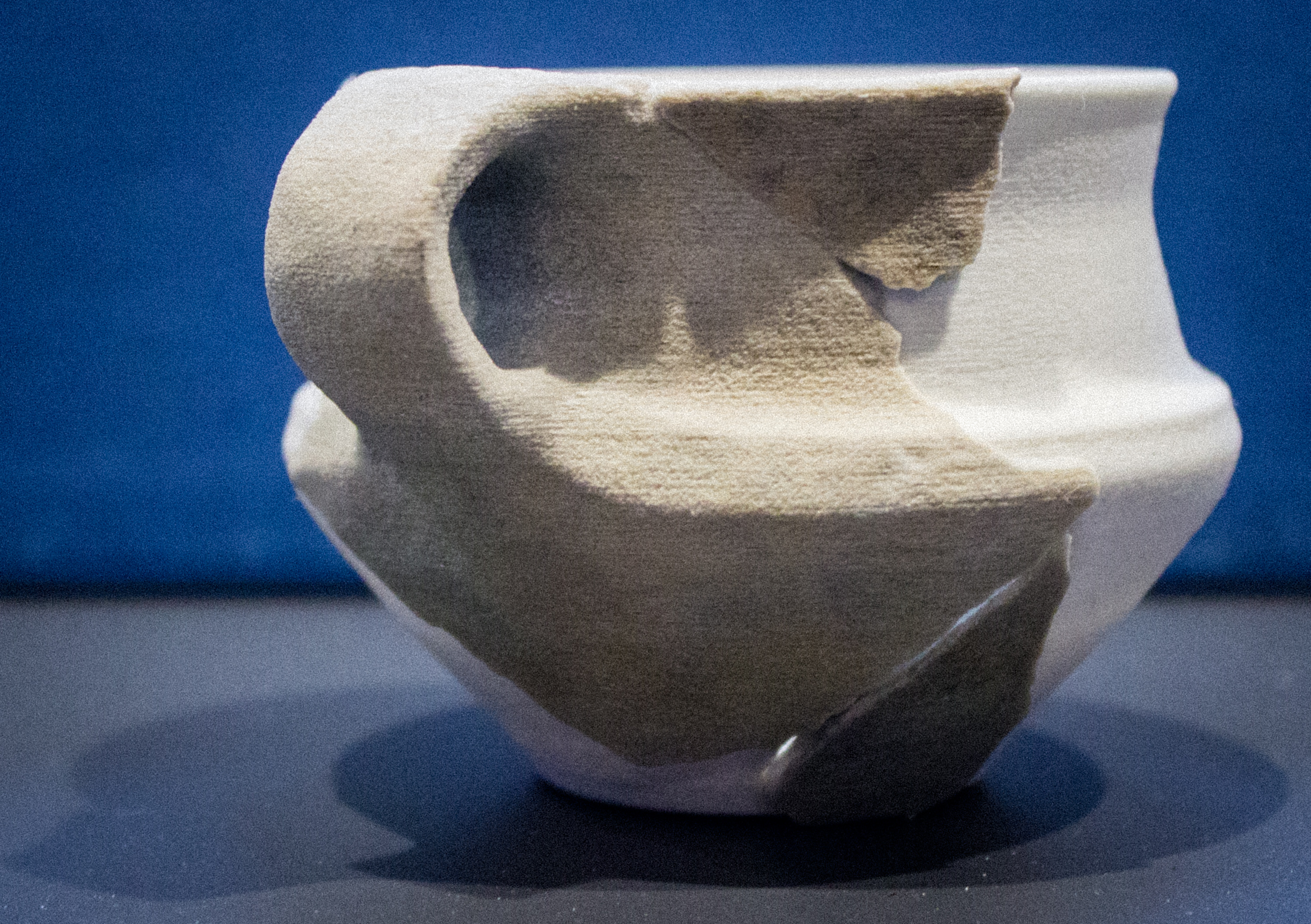

Powder printer

Full-color prints like the one below made possible by gypsum printers like the Polyjet 660pro. They can colour the surface in a very real style, so the texture from original objects can be printed. Annotations and markings can also be added to the Object.

Because of the production process the builds can be bigger than normal plastic printers, also hollow prints or moving parts can easily be achieved.

Print of the “Plauer” Cup

The digitized surface of the cup is completely applied to the printed objects including small geometric details as well as the texture. This leads to a very realistic impression. This gets even more real because of the used gypsum that produces a very similar surface and feels like pottery. Even the weight of a gypsum object is more like the original than a plastic print.

The original find was digitized after it was found at an excavation of the Freie Universität Berlin using photogrammetry. It consists of several shards providing a full profile of the cup and a reconstructed part. All Objects there aligned and made printable using the free Software Blender.

Although it would be possible to reconstruct the missing parts in a way that looks more real to make a more realistic cup. But I think it is more honest to make the reconstructed parts clearly visible to show what an archaeologist did find and not what he wished to find.

Applications of 3D printing in Archaeology

The digitizing of heritage objects is a very promising workflow providing many opportunities to display, replicate and share finds in a different context and ways. Digital objects can be almost distributed and analyzed without any harm to the original.

Prints of digitized objects can be used in schools, museums, at home or university to experience historical objects in a brand-new way. It is even a good way to let sight impaired, or blind people get an impression of archaeological objects. Because of their relatively low price, they can be sold in shops and are an alternative to a black market trade of artifacts.

I, personally, think printed objects can become a great opportunity to get a new haptic experience on an otherwise mostly visual field.

Are you interested in 3D scans, prints, reconstructions, workshops or questions?